The custom t-shirt printing industry has seen remarkable advancements in recent years, driven by the rapid pace of technological innovation. What was once a niche market for screen printing and heat transfers has transformed into a dynamic industry where creativity meets technology. Today, custom t-shirts are no longer just a way to add logos or slogans to the fabric. With new tools and techniques, businesses and individuals can now create intricate, personalized designs quickly and affordably. In this article, we’ll explore how emerging technologies are reshaping the world of Personalized t-shirt customization and what it means for the future of this creative industry.

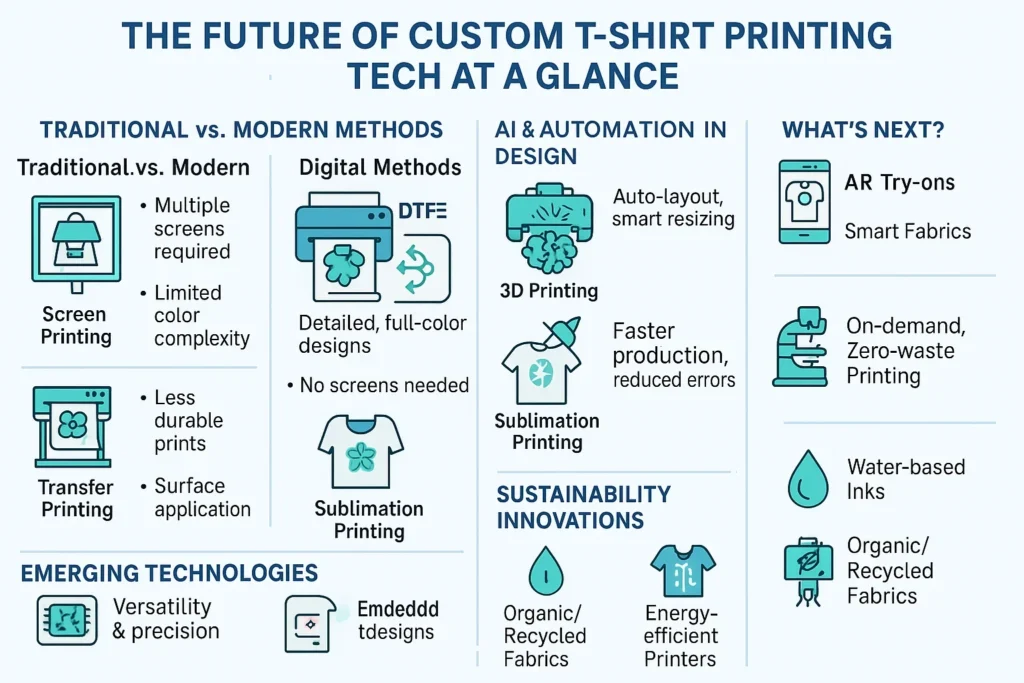

The Shift from Traditional to Digital Printing

Before we delve into the cutting-edge technologies shaping the evolution of shirt printing, it’s essential to understand the industry’s origins. Traditional methods, such as screen printing and transfer printing, have been the backbone of the custom apparel market for decades. While these techniques were effective, they came with significant limitations. Screen printing, for example, requires separate screens for each color in a design, which makes it time-consuming and costly for smaller runs or highly detailed images. Transfer printing, while faster, often produced lower-quality prints that could fade or peel over time.

However, the rise of digital printing technologies has significantly altered the landscape. Digital printing methods, such as Direct-to-Garment (DTG) and sublimation printing, have opened up new possibilities. These techniques enable the creation of high-quality, full-color designs that can be printed directly onto fabric, eliminating the need for multiple screens or complex processes. The transition from traditional to digital printing has made t-shirts more accessible, faster to produce, and more flexible in terms of design complexity.

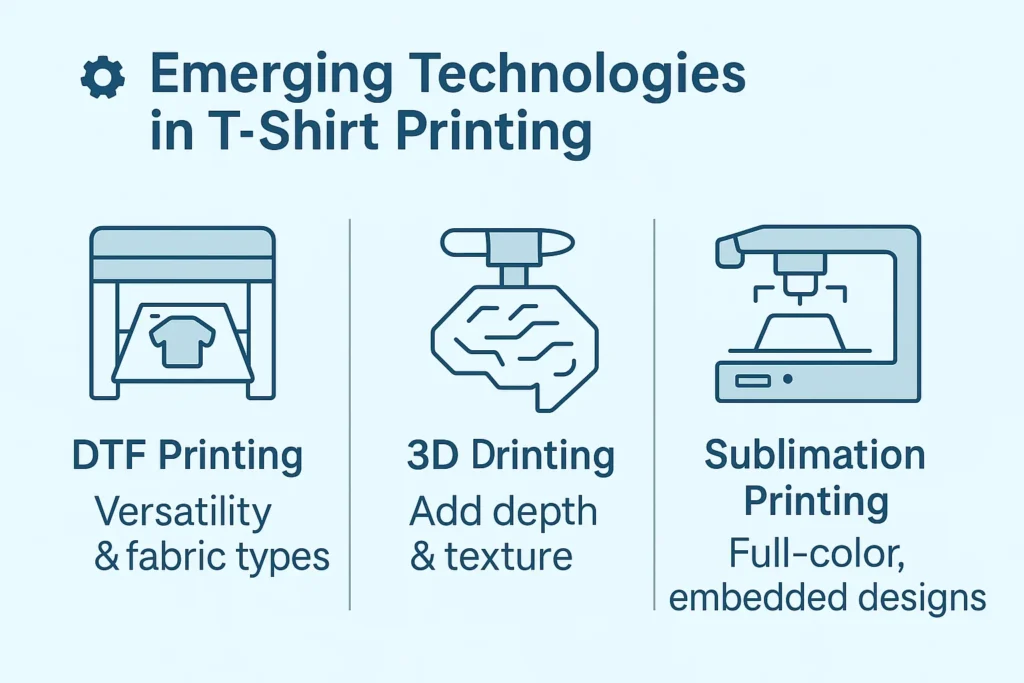

The Rise of Emerging Printing Technologies

As digital printing continues to evolve, several new technologies are emerging that promise to make custom shirt printing even more efficient and innovative. Let’s take a closer look at some of these game-changing technologies that are shaping the future of custom apparel.

Direct-to-Film (DTF) Printing: Versatility and Precision

One of the most exciting developments in garment printing is Direct-to-Film (DTF) printing. This process involves printing designs onto a special film, which is then transferred onto the fabric using heat and pressure. The advantage of DTF printing is its ability to print vibrant, high-quality designs on a wide variety of fabrics, including cotton, polyester, and blends.

DTF printing offers incredible precision, enabling the creation of intricate designs with fine details. What makes this technology stand out is its ability to print on both light and dark fabrics, a feature that can be challenging with other methods, such as sublimation. DTF station printing is especially beneficial for small businesses and independent creators, as it requires minimal setup costs and can produce excellent results without the need for extensive equipment or large production runs. The result is a durable, soft-to-the-touch print that maintains its vibrancy even after multiple washes, making it a popular choice for high-quality, long-lasting custom clothing.

3D Printing: Adding Depth and Texture to Custom T-Shirts

Another innovative technology making waves in the custom apparel industry is 3D printing. While 3D printing has been primarily associated with industrial and product design, its application in fashion and t-shirt customization is now emerging. This technology allows designers to create intricate textures, raised designs, and even sculptural elements on t-shirts, adding a whole new dimension to the garment.

For example, 3D printing can be used to create logos or patterns that stand out, giving the t-shirt a unique, tactile quality. The ability to add depth and texture to a t-shirt design opens up exciting possibilities for creating bold, fashion-forward apparel. While 3D printing for t-shirts is still in its early stages, it is expected to become more mainstream in the coming years, providing designers with the ability to experiment with new textures and effects that go far beyond traditional printing methods.

Sublimation Printing: High-Quality All-Over Designs

Sublimation printing is another technology that has become increasingly popular in the printed t-shirt world, particularly for creating all-over designs. Unlike other printing methods that apply ink to the surface of fabric, sublimation printing uses heat to turn dye into gas, which then bonds with the cloth fibers. This creates a vibrant, permanent design that is embedded in the fabric rather than being applied on top.

Sublimation printing works best on synthetic fabrics, such as polyester, and allows for full-coverage prints that can cover the entire surface of the t-shirt. The benefit of sublimation is that the designs won’t fade, crack, or peel over time because the dye becomes part of the fabric itself. While sublimation is limited to polyester or polyester-blend fabrics, it’s an excellent option for creating vibrant, all-over designs, making it particularly popular for sports apparel, promotional items, and fashion lines that require bold, full-color prints.

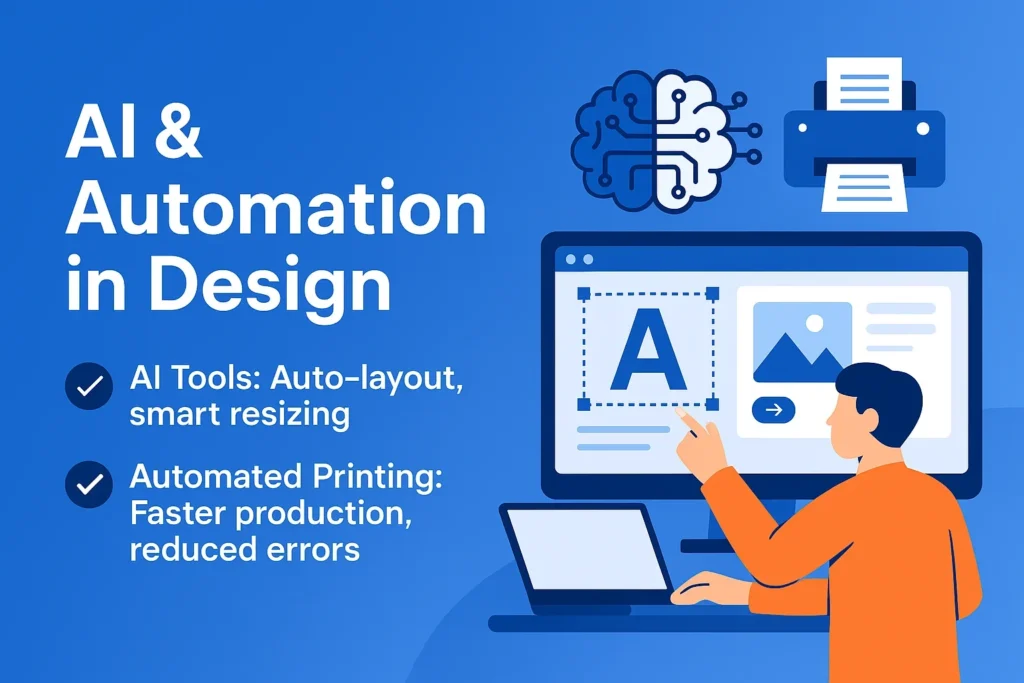

AI and Automation: The Future of T-Shirt Design and Production

As printing technologies evolve, so too do the tools used to create and produce t-shirt designs. Artificial intelligence (AI) and automation are now playing a crucial role in simplifying the design process and improving production efficiency.

AI-Powered Design Tools for Custom Apparel

AI-driven design software is revolutionizing how individuals and businesses create custom shirt designs. These tools utilize machine learning to enable users with little to no prior graphic design experience to develop professional-grade designs. AI-powered platforms can suggest color schemes, optimize layouts, and even generate entire designs based on user input.

For example, if a customer uploads a logo or image, AI tools can automatically resize, position, and adjust the image for printing, ensuring that the design fits perfectly on the t-shirt. This is especially helpful for businesses that need to create large volumes of shirts quickly, as it streamlines the design process and minimizes human error.

Automated Printing Systems: Streamlining Production

Another way automation is transforming Personalized shirt printing is through the use of automated printing systems. These systems utilize robotics and advanced machinery to apply designs to garments quickly and accurately, thereby reducing human error and increasing production efficiency. Automated printing enables businesses to fulfill large orders more efficiently, enhancing scalability and consistency throughout the production process.

The automation of printing systems has also made it easier to print multiple designs in a single run, allowing businesses to produce a variety of custom shirts with minimal downtime. This efficiency makes automated printing ideal for businesses with high-volume orders or those that specialize in on-demand printing.

Sustainability in Tailored T-Shirt Printing

As sustainability becomes an increasingly important concern for both consumers and businesses, the Tailored Garment printing industry is stepping up to meet these demands. New technologies and practices are helping to reduce waste and lower the environmental impact of t-shirt production.

Eco-Friendly Inks and Materials

One of the key areas where sustainability is being prioritized is in the choice of inks and materials used in the printing process. Water-based inks are gaining popularity due to their non-toxic and eco-friendly nature. These inks are free from harmful chemicals like PVC and phthalates, which are often found in traditional plastisol inks. In addition to being safer for the environment, water-based inks provide a softer, more comfortable feel to the fabric.

Sustainable materials, such as organic cotton and recycled fabrics, are also being used in the production of clothing. By incorporating eco-friendly fabrics and printing techniques, businesses can reduce their carbon footprint and offer customers more environmentally conscious products.

Energy-Efficient Technologies

Emerging printing technologies, such as DTF station printing, are more energy-efficient than traditional screen printing methods, which require large amounts of water and energy. By reducing the energy consumption of the production process, these newer technologies contribute to a more sustainable Garment printing industry.

The Future of Custom T-Shirt Printing: What’s Next?

Looking ahead, the evolution of t-shirt customization holds exciting possibilities. Augmented reality (AR) may become a significant part of the custom apparel experience, allowing customers to virtually try on designs before making a purchase. Additionally, wearable technology is expected to play a bigger role in fashion, with t-shirts incorporating smart fabrics that can interact with other devices.

As these technologies evolve, Custom clothing prints will become more customizable, faster, and more sustainable. Whether for personal use, branding, or fashion, the New Era of Made-to-order Custom clothing prints holds endless potential.

Conclusion

The Made-to-order Garment printing industry is experiencing a technological revolution. From DTF station printing to AI-powered design tools and sustainable materials, the evolution of custom apparel is brighter than ever. These emerging technologies are making the design and production process faster, more creative, and environmentally friendly. As the industry continues to innovate, it’s clear that the possibilities for t-shirt customization are limitless, providing both businesses and consumers with new opportunities to create unique, high-quality apparel.