Disclaimer: This article is for informational purposes only and is not financial or business advice. Readers should assess their own circumstances or consult a professional before making decisions.

Want to save money & start making more profit today? Retailers fantasize about a slim, profitable business model. Why? Because of low costs :

- Higher profit margins

- Increased cash flow

Problem:

Retailers are hemorrhaging money via inefficient Stock management. Stockouts, overstocks, and other inventory control issues can result in costs of up to 11% of annual revenue.

If you’re not in control of your inventory, you’re flushing money down the toilet.

This article reveals the tactics successful retailers implement to cut costs, optimize efficiency, and save thousands through better Stock management.

Let’s do this!

What You’ll Learn:

- Why Retail Inventory Control Is Costing You Money

- What Makes Efficient Stock Management Different?

- Proven Cost-Reduction Tactics

Why Retail Inventory Control Is Costing You Money

Weak Warehouse management is killing your bottom line. If your inventory practices are broken or disorganized, here are three reasons why it’s costing you big money.

Your Money Is Tied Up In Dead Stock

Excess inventory is dead weight. Think of it as cash sitting in a vault, earning nothing.

Why? Because money that should be growing a business is instead rotting on a shelf. On average, enterprises hold $142,000 worth of excess inventory (up to $300,000 in some industries), which can’t be invested.

Dead stock = Dead profit.

The issue of overstocking compounds across thousands of products, each one sucking away at your cash flow. Efficient Warehouse management stops this problem at its core by precisely forecasting demand and fine-tuning order quantities.

Storage And Handling Costs Keep Climbing

Ready for some mind-blowing news?

Fulfillment costs, including warehousing & shipping, make up 20% of total inventory expenses, which is a huge reason why businesses are optimizing storage & distribution.

Here’s the bad news:

Each extra unit in your warehouse eats away at profits: rent, utilities, insurance, labor. The costs stack up quickly when you overstock.

So don’t overstock. Efficient retail inventory management software will help you maintain the exact proper stock levels, minimize these hidden expenses, and always have your hot products in stock.

Opportunity Costs Are Devastating Your Growth

One of the most underrated consequences of poor Warehouse management is opportunity cost. Money sitting in excess inventory can’t be spent on new products, marketing campaigns, or store improvements.

Retailers that optimize inventory liberate this capital and put it back to work in growth activities. It’s a force multiplier effect that compounds over time.

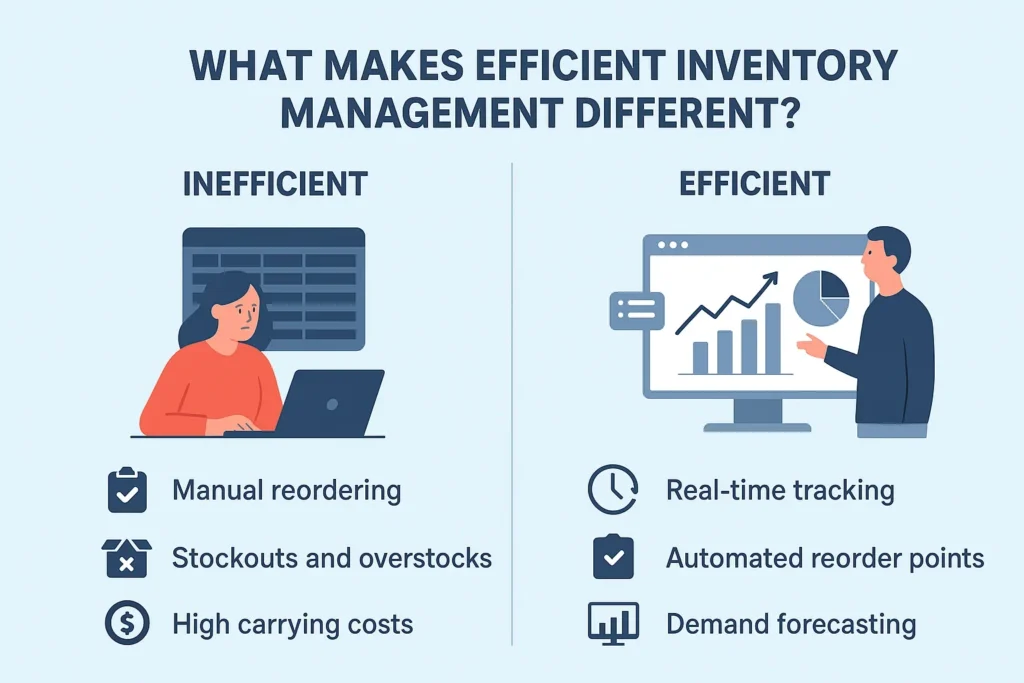

What Makes Efficient Inventory Management Different?

Efficient inventory control is different because it’s precise, not guesswork. Successful retailers need systems that know EXACTLY what’s in stock, when it’s going to run out, and when to order more.

We’re talking:

- Real-time stock visibility

- Automated reorder points

- Demand forecasting

- Multi-channel syncing

Legacy Warehouse management systems were built on spreadsheets and manual labor. Here’s the truth. Manual processes are losing you money daily.

Automated systems use data and algorithms to eliminate inefficiencies. When you know EXACTLY where every product is and when you need to reorder, two things happen:

- You place orders in the right quantities at the right time

- Carrying costs plummet

The secret is to implement solutions that give you 100% control of your inventory cycle.

Proven Cost-Reduction Tactics

Now the tactics that actually work. These 6x approaches have helped retailers drop their inventory costs by 20-30%. Read all the tactics, choose what’s relevant to your business, and start implementing.

Tactic 1: Implement ABC Analysis

Not all products are created equal. When it comes to inventory optimization, this simple fact cannot be overstated.

Here’s how ABC analysis works: You divide your inventory into three categories based on value and sales velocity.

A-items are high-value, fast-moving products that represent 80% of revenue from 20% of inventory. B-items have a moderate value and medium velocity. C-items are low-value, slow-moving.

Companies that use ABC analysis reduce excess inventory by up to 25%. Focus time & energy on managing A-items perfectly, while automating control over B and C.

Tactic 2: Use Demand Forecasting Technology

Want a more straightforward way to predict what customers will buy? Demand forecasting technology could be your magic bullet.

With 50% less inventory and the same customer service levels (give or take a few weeks), companies that implement advanced forecasting have a massive edge over the competition.

Forecasting systems crunch historical sales data, seasonality patterns, and market trends to predict future demand. The result? You only order what you will sell, reducing both stockouts and overstock.

Tactic 3: Optimize Reorder Points And Quantities

Late reorder points are hemorrhaging your business. Optimal reorder times ensure you don’t run out while minimizing carrying costs.

Calculate your reorder point by adding the average demand during the lead time to the safety stock. Savvy retailers use data to set optimal safety stock levels, balancing service levels & cost.

Order quantities should be determined by the economic order quantity (EOQ) that considers ordering costs, carrying costs, & demand.

Tactic 4: Implement Just-In-Time Principles

Just-in-time (JIT) inventory can dramatically slash your carrying costs. The principle is simple: Receive inventory exactly when you need it, not before.

Begin with fast-moving A-items. Collaborate with suppliers to shorten lead times and increase delivery frequency. The benefits are immediate: lower storage costs, reduced obsolescence risk, and improved cash flow.

But keep in mind. JIT requires excellent supplier partnerships & predictable demand.

Tactic 5: Leverage Real-Time Inventory Tracking

To meet rising customer expectations for stock accuracy and on-time delivery, 67% of businesses plan to implement real-time inventory systems by 2025.

Real-time inventory tracking gives you up-to-the-minute visibility into actual stock levels, sales velocity, reorder needs, and movements. When you can see exactly what’s going on with inventory, you make better decisions, faster.

Automate data collection using barcode scanning, RFID, or IoT sensors. It’ll pay for itself in improved accuracy and reduced labor costs.

Tactic 6: Automate Routine Inventory Tasks

Manual inventory is expensive and riddled with errors. Automated inventory management systems cut stockouts by 30% while reducing labor costs.

Key processes that can be automated include reorder point calculations, purchase order generation, stock level monitoring, and performance reporting.

Automation removes the human error factor, plus it frees your team up to work on strategic, high-value activities rather than rote data entry.

Wrap Up

It’s not just a task; it’s an opportunity to control your profits via smart cost-cutting. Savvy retailers who optimize their inventory control see significant improvements in cash flow, lower costs, and customer satisfaction.

Start with one or two tactics, and get cracking on implementation.

Here’s the brutal truth. The cost of doing nothing is greater than the cost of making changes. Every day that passes is another day of money left unearned.

Please select your favorite tactic from this list and begin it tomorrow. Your cash flow will thank you!