The micro-manufacture industry dubbed the ‘age of micro-manufacturing’ is now more sophisticated than ever, as both tolerances and complexity are measured in microns. Components such as those found in defense and medical instruments are being used internationally. Electrical Discharge Machining (EDM) is one such instrument that allows for unprecedented flexibility. High-accuracy EDM is entrenched in all the advanced fields, including the aerospace industry, as it continues expanding because it offers manufacturers complex 3-D shapes that traditional machines cannot provide.

In this blog, we will show how EDM transforms the fabrication of components, what makes them ideal for nivel micrones, and last but not least, how collaboration with a verified CNC cutting service allows guaranteed, scalable results for high-level B2B clientele.

Why is Precision EDM an Industry-Changing Mechanism

It is a fireless process that uses electrical discharges between a non-contact electrode and a dielectric fluid-suspended conductive workpiece. An Electro-Discharge Machine removes material one cinder at a time, increasing the ease with which features, deep cavities, sharp internal corners, and hardened materials are machined. These are impossible to cut using average CNC methods.

| Feature | Description |

|---|---|

| Process Type | Fireless material removal using electrical discharges between a non-contact electrode and a conductive workpiece in dielectric fluid. |

| Material Removal | It removes material one cinder at a time and is ideal for intricate, hardened parts. |

| Tolerances | Capable of achieving very tight tolerances of ±0.002 mm or better. |

| Mechanical Stress | It is a non-contact, force-free machining process without mechanical stress or deformation. |

| Material Compatibility | Effective on complex or exotic materials such as titanium, Inconel, carbide, and hardened steels. |

| Surface Finish | Produces a fine surface finish, often eliminating the need for further polishing or post-processing. |

| Geometric Freedom | Ideal for unrestricted geometries including micro-holes, sharp internal corners, thin walls, and deep cavities. |

The following are notable benefits of Micron-Level EDM:

- High Capability: Capable of achieving tolerances of ±0.002mm or better.

- No mechanical stress: There is no deformation risk since it is a non-contact method, and no tool force is involved.

- Machining complex or exotic materials: principal shape portions of titanium, Inconel, carbide, and hardened steels can all be EDM machined.

- Surface quality: A fine finish is frequently required and does not need further polishing or treatment.

- Unrestricted geometries: Works best with micro-holes, thin walls, and other complex internal features.

High Accuracy is an appreciated and essential technology for many EDM manufacturers, especially in high-tech industries such as pyrotechnics, aerospace, and microelectronics.

Where Precision EDM Excels: Applications in High-Tech Sectors

Understood to be the preferred method wherever small, strong, and ultra-precise components are required. Below are several industries where EDM plays a critical role.

EDM enjoys ultra-precision turbine blades with micro-stream cooling holes and structural components with inner working ultra-fine holes for severe design detail and tolerance demands. Wire EDM produces profile-cut hardened alloys in aircraft applications, and Sinker EDM shapes high-strength flight-critical parts.

Medical Devices and Implants

Implants and surgical instruments, such as titanium bone screws and tools used in minimally invasive surgery, require intricate detailing and no burrs. EDM enables manufacturers to optimize such details for medical-grade devices and tools.

Mold and Die Making

An ultra mold cavity for die EDM can effortlessly automate copy-milling drill work on intricately sourced pneumatic stamps and injection stamps. The precision repeatability EDM offers and the ability to work with tempered steel assure that high-caliber molds are produced.

Semiconductor and Electronics

EDM works exceptionally well for miniaturization designs like die molds and micro-connector outlines with sharp internal corners and small radii, as many materials can be used, such as copper, graphite, tungsten, etc. With miniaturization comes the requirement for precision on a micron level.

Precision Optics and Instrumentation

Complex fabrications built from hard, machined parts are quite difficult to replicate. Metrology tools or high-grade optical components require accurate dimensions and a defined surface finish. With EDM, repeatability across multi-component instruments is possible, which makes it easier to develop precision-grade measuring tools and optical components.

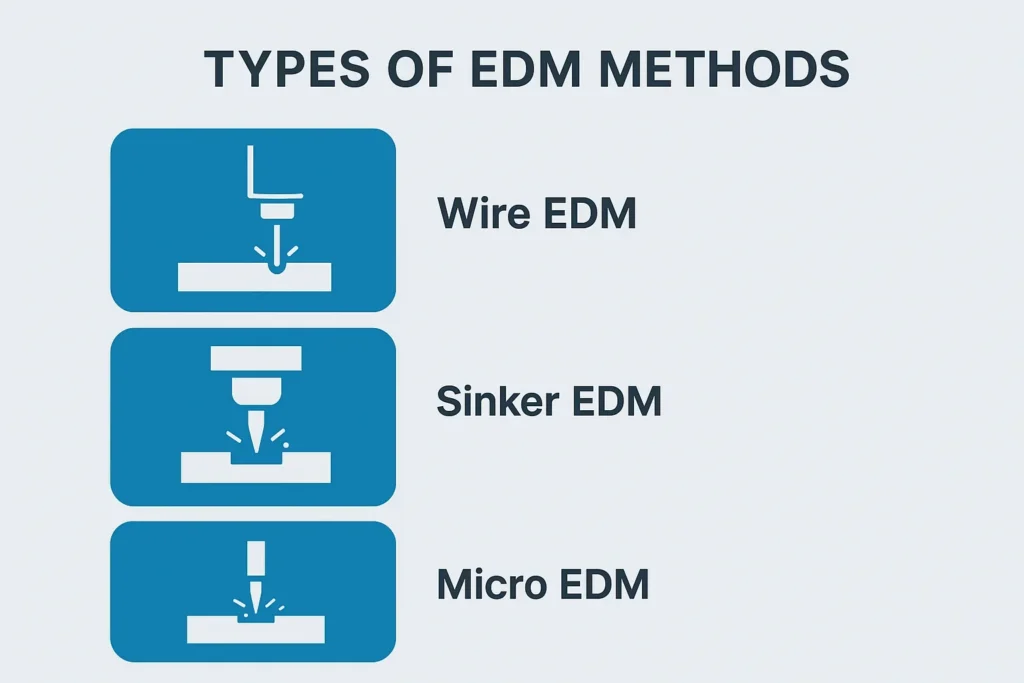

Types of EDM Methods in Micron-Level EDM Milling

There are a number of different specialized techniques of EDM, each having its own distinct benefits based on part requirements:

Wire EDM

Wire EDM utilizes a thin wire (typically made of brass or copper) as an electrode, which cuts through the workpiece like a band saw. It is best suited for detailed 2D profiles and small holes, which are complex shapes in hardened metals.

Sinker EDM

Also known as die-sinking EDM, this type utilizes a custom-shaped electrode that ‘sinks’ into the workpiece to create complex cavities. It is common in mold making and for components with internal geometries that cannot be reached by other means.

Micro EDM

Applying traditional EDM technology at the micron scale is called micro EDM, which can produce features smaller than 50 microns. Some of its typical applications are microfluidic devices, micro-molds, and precision watch components.

EDM Drilling, also referred to as Hole Popping

EDM hole drilling makes it possible to manufacture very small and deep holes, frequently in locations where regular drills fail. This is helpful in aerospace for cooling holes and electronics for dense circuit paths.

A reputable CNC precision machining company will commonly fuse these EDM techniques with standard milling and turning processes to produce complete parts for stringent B2B requirements.

How Precision CNC Machining Companies Apply EDM

Integrating EDM equipment into existing workflows creates the most optimal workflows in manufacturing processes. A precision CNC machining company utilizing technology is able to:

- Merge operations: EDM is commonly paired with multi-axis CNC machining, Swiss turning, and grinding to finish more complex spatial requirements.

- Speed up prototyping: EDM significantly improves the pace of prototype development by being able to cut through hardened materials without special routing tools.

- Enhance consistency of output: Sustained, automated EDM systems working together with active QC enforce strict tolerances over extensive production cycles.

- Enhance efficiency over material wastage: EDM provides high accuracy and minimal wear on cutting tools, which significantly increases the usable yield from costly materials like titanium and carbide.

In many cases, advanced CNC Precision Machining Company departments have begun marketing micron-level EDM as a peripheral, value-added resource because of its influence on parts design, especially by industries that control the extremes of size and performance.

Choosing the Right EDM Partner for Your Business: The Best EDM Partners

Choosing a precision EDM manufacturing partner involves more than simple procurement; it blends business and strategy. Supporting information is as follows for consideration:

Proven EDM Expertise

Each EDM partner should be able to showcase some of their work through case studies. Adequate partners will possess industry-specific custom capabilities complete with parts of specific complexity or tolerance level requirements.

Equipment Cuts

Premium businesses will have more EDM Machines for wire, sinker, and micro-EDM. Premium machines will also possess advanced controls, automated tool changers, in-process inspection, and self-checks.

Design Support

Assist in designing CAD models for the projects, assuring the essential characteristics and functions are retained with the required fine tolerances.

Material Compatibility

Acquaint yourself with the companies that manufacture specialty materials made from conductive ceramics, exotic alloys, stainless tool steel, or even steel.

Quality Systems

A set of standards (ISO 9001, AS9100, ISO 13485), along with having a system of documented inspection and checklist processes characterized as traceability and defect prevention

Selecting a precision CNC machining company gives partners with some knowledge of EDM the ability to provide far more than just parts. With support for your entire project lifecycle, they should guarantee reliability and quality in addition to great engineering insight.

Conclusion

Advanced EDM is essential in micron-level innovations to fulfill the expectations of smaller and more intelligent components. It enables the production of complex parts in robust materials and flawless sizes while being economically feasible.

Every company, whether in various sectors, including aerospace, medicine, electronics, or any other sector relying on CNC machinery, should collaborate with trusted precision CNC companies to help them sustain the rapidly changing demands of the modern world. When considering tight tolerances in ED, it is vividly clear that EDM is no longer a specialized service but rather an essential tool.