Disclaimer: This article is for informational purposes only and does not constitute professional safety advice. Always consult your employer’s safety guidelines and certified occupational health experts when selecting protective footwear for your work environment.

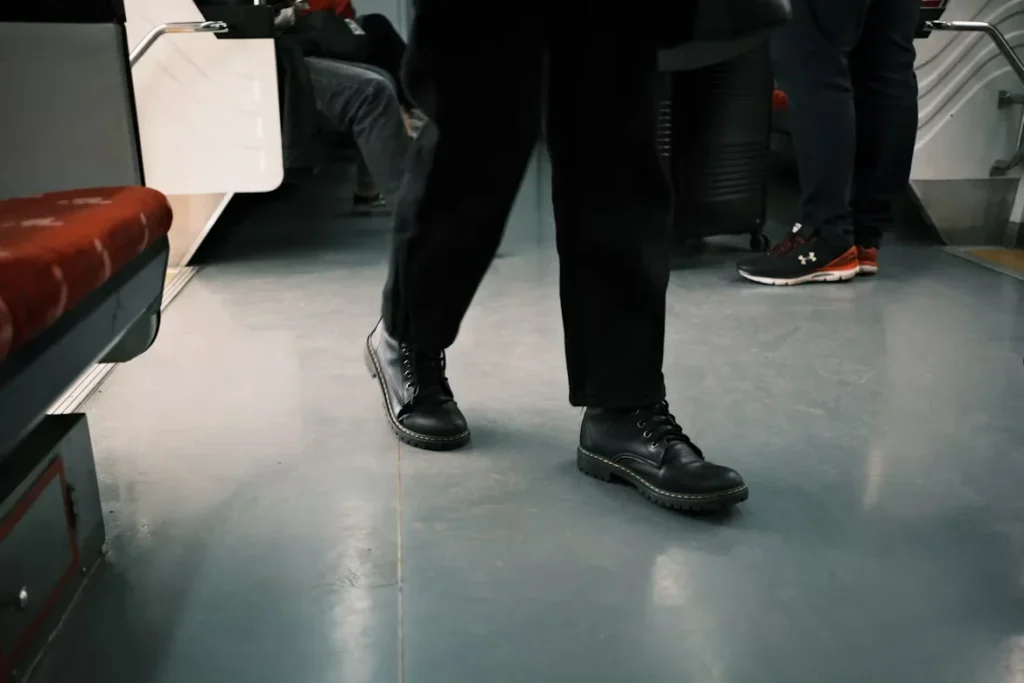

The terms “non-slip” and “slip-resistant” get used interchangeably in footwear marketing, but they describe different approaches to preventing workplace accidents. Understanding these differences helps choose safety footwear that works rather than just sounds impressive.

Both types aim to reduce the risk of slipping, but they achieve this through different design philosophies and performance standards. Here’s what separates them and when each type makes sense.

Understanding Non-Slip Shoes

Non-slip footwear is specifically designed to minimize slipping on wet or oily surfaces through certified testing and specialized construction. These shoes meet strict performance requirements when evaluating slip resistance against standardized surfaces.

- Testing standards: Non-slip footwear undergoes rigorous testing to earn certification. The shoes must demonstrate specific levels of traction on wet and oily surfaces before earning a non-slip designation.

- Tread design: Non-slip footwear features unique tread patterns engineered for maximum grip on slick surfaces. These patterns channel liquids away from the contact area while maintaining surface contact for better traction.

- Material composition: Advanced rubber compounds in non-slip outsoles provide superior grip on greasy surfaces. The rubber formulations resist oil absorption while maintaining flexibility across a wide range of temperatures.

Quality men’s work shoes often incorporate these non-slip technologies for demanding work environments where safety can’t be compromised.

Exploring Slip-Resistant Footwear

Slip-resistant footwear focuses on providing better grip across various surfaces without necessarily meeting the strict testing standards required for non-slip certification. This broader approach makes them versatile for multiple environments.

- Design philosophy: Slip-resistant footwear optimizes traction through the outsole design and material selection, rather than relying on certified testing protocols. The emphasis lies on practical performance across diverse conditions.

- Versatile applications: This footwear is well-suited for various surface types, ranging from dry floors to moderately wet conditions. The design accommodates varying workplace demands without specializing in extreme slip prevention.

- Construction benefits: Slip-resistant footwear often features more flexible designs that balance traction with comfort. The outsoles provide a reliable grip while maintaining walking comfort during long work shifts.

Key Performance Differences

| Feature | Non-Slip Shoes | Slip-Resistant Shoes |

| Testing Standards | Certified slip resistance testing | General traction optimization |

| Primary Use | Wet, oily, greasy surfaces | Various surface conditions |

| Tread Design | Specialized patterns for liquid displacement | Versatile patterns for general grip |

| Material Focus | Oil-resistant rubber compounds | Balanced rubber for multiple surfaces |

Identifying Slip-Resistant Features

- Tread patterns: Look for deep grooves that channel liquids away from the sole contact area. Effective patterns create multiple grip points while preventing liquid buildup under the shoe.

- Outsole materials: Quality slip-resistant shoes use rubber compounds designed for traction. The material should feel slightly tacky to the touch while remaining durable enough for extended use.

- Certifications: Certified safety shoes display markings indicating compliance with occupational health and safety standards. These markings validate the shoe’s slip-resistance claims.

- Construction quality: Reliable slip-resistant footwear features a solid outsole attachment and reinforced high-wear areas. Poor construction undermines even the best tread design.

Workplace Applications

Food Service Environments

Food service workers are constantly exposed to wet surfaces, grease, and spills. Slip-proof shoes excel in these conditions because they’re explicitly tested for such environments. The specialized tread patterns and oil-resistant materials handle kitchen conditions effectively.

Non-skid shoes are adequate in food service but may not provide the same level of protection during peak spillage times or when exposed to heavy grease.

Healthcare Settings

Healthcare environments present mixed challenges with both wet surfaces and various floor types. Non-skid shoes often work well in this situation because they adapt to multiple surfaces while providing sufficient traction.

Non-slip footwear works exceptionally well in areas with frequent liquid exposure, such as surgical suites or patient care areas where spills occur regularly.

Industrial and Maintenance Work

Industrial environments vary significantly in surface conditions and hazards. Slip-resistant footwear typically offers better versatility for workers who move between different areas with varying surface types.

Non-slip footwear is most effective in specific industrial areas with consistently wet or oily conditions, such as machinery maintenance areas or chemical processing facilities.

How to Choose the Right Safety Footwear

- Assess your environment: Identify the primary slip hazards in your workplace. Consistent exposure to oils and liquids favors non-slip shoes, while varied conditions might benefit from slip-resistant options.

- Consider comfort needs: Long shifts require shoes that balance safety with comfort. Non-skid shoes often provide more walking comfort, while Maximum grip shoes prioritize maximum protection.

- Evaluate certification requirements: Some workplaces mandate specific safety certifications. Check whether your employer requires certified non-slip footwear or accepts general Anti-slip shoes.

- Think about durability: Consider how often you’ll replace the shoes. Non-slip footwear usually costs more initially but may last longer in harsh conditions due to its specialized construction.

Expert Safety Insight

According to the Bureau of Labor Statistics, slips and falls account for 27% of workplace injuries annually. Occupational safety specialist Dr. Jennifer Walsh notes, “Proper footwear selection reduces slip incidents by up to 67% when matched correctly to workplace hazards.”

This data highlights why selecting suitable safety footwear is more important than simply choosing the most expensive option available.

Maintenance and Care

- Regular cleaning: Remove grease and debris from tread patterns regularly. Clogged treads lose effectiveness regardless of the original design quality.

- Outsole inspection: Check for wear patterns that indicate reduced traction capability. Replace shoes when the tread depth diminishes significantly or when outsole damage becomes apparent.

- Proper storage: Store safety shoes in dry areas to prevent material degradation. Extreme temperatures can impact the performance of rubber compounds over time.

Quality brands like Lugz design their safety shoes for durability and easy maintenance, helping extend shoe life while maintaining safety performance.

Making the Smart Choice

High-traction grip shoes are ideal for environments with consistently wet or oily conditions, where maximum slip protection is essential. They justify higher costs through superior performance in demanding conditions.

Anti-slip shoes offer excellent value for diverse work environments where versatility is more important than specialized protection. They strike a balance between safety, comfort, and cost-effectiveness.

The right choice depends on an honest assessment of workplace hazards, comfort requirements, and budget considerations. Both types significantly improve safety compared to regular shoes, but matching the technology to specific needs maximizes protection and value.

Investing in proper safety footwear prevents injuries while supporting productivity. Whether choosing non-slip or anti-slip shoes, prioritizing quality construction and appropriate features assures long-term satisfaction and protection.

Frequently Asked Questions

What’s the main difference between non-slip and slip-resistant shoes?

Maximum grip shoes undergo certified testing for slip resistance on wet and oily surfaces, while Anti-slip shoes provide general traction optimization without specific certification requirements. Slip-proof shoes offer specialized protection for extreme conditions.

Do I need certified non-slip shoes for food service work?

These environments with frequent exposure to grease and liquids benefit significantly from certified Maximum grip shoes. The specialized patterns and oil-resistant materials enable kitchen conditions to be handled more effectively than with general slip-resistant footwear.

How can I tell if shoes are truly slip-resistant?

Look for certification markings, deep patterns that channel liquids, and rubber outsoles that feel slightly tacky. Quality Anti-slip shoes also feature solid construction and reinforced high-wear areas for durability.