The process of microchip assembly is one of the most intricate and precise manufacturing feats in modern technology. Each microchip, the heart of smartphones, computers, and countless digital devices, is built through a series of highly controlled steps that demand absolute accuracy.

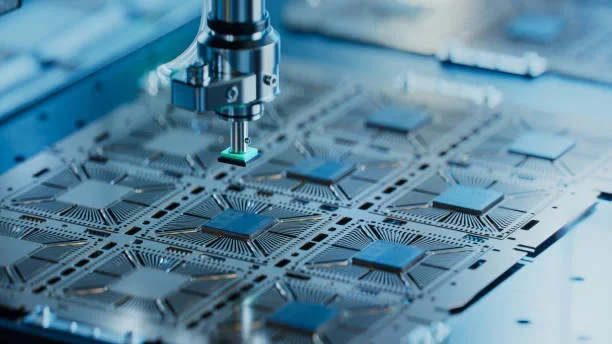

During assembly, microscopic components are carefully placed onto circuit boards through automated machinery that ensures exact alignment. These components, often smaller than a grain of sand, must connect perfectly to enable seamless electrical communication within the chip. Even the slightest deviation or dust particle can cause failure, making precision and cleanliness vital at every stage.

The process typically begins with wafer fabrication, where thin slices of silicon are imprinted with complex patterns that form transistors and circuits. Once fabricated, these wafers are cut into individual chips and then mounted onto boards using advanced robotics. Soldering and inspection follow, with each step monitored through automated systems and high-resolution imaging tools.

Modern cleanrooms, where assembly takes place, are up to a thousand times cleaner than hospital operating rooms. Engineers wear full-body suits to prevent contamination, ensuring that every microchip produced meets exacting global standards for performance and reliability.

As demand for faster, smaller, and more efficient electronics grows, manufacturers continue to refine microchip assembly techniques, pushing the limits of precision and automation. This innovation drives the next generation of computing, powering technologies from artificial intelligence to space exploration.